When it comes to linear actuators, there are various types available that utilize electromagnetic principles. They generally convert electrical energy into linear motion. These actuators find applications in a wide range of industries. From aerospace to medical equipment, robotics, and industrial automation, they help improve the efficiency and performance of machines.

So, today, we explore the world of electromagnetic linear actuators. Here you discover the different types, their operating principles, design considerations, and applications. You also get to compare the different electromagnetic linear actuators at a glance. Let us get started.

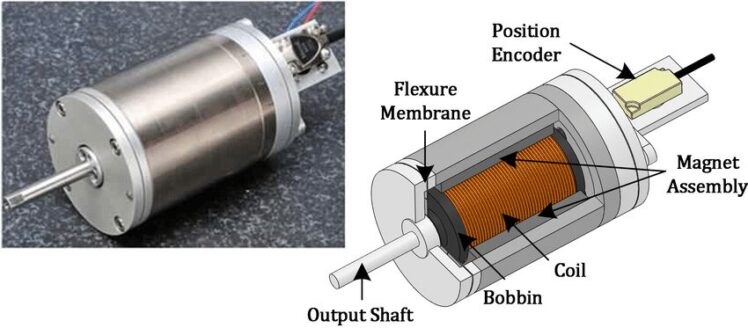

1. Voice coil actuators

Operating principles

These compact and efficient actuators operate based on the interaction between a magnetic field and an electromagnetic coil. The coil moves within a magnetic field, generating linear motion. This technology offers precise control and high acceleration rates. It is, therefore, ideal for applications where speed and accuracy are paramount.

Design considerations

-

- Coil types: When considering voice coil actuators for your project, there are a few design considerations to keep in mind. Firstly, you’ll come across different coil types. They include iron core, air core, and hybrid. Each type has its own advantages, so choose the one that suits your specific needs.

- Magnet types: Secondly, selecting the right magnet type is crucial for optimizing performance. You may choose from permanent magnets or electromagnets, depending on the application requirements.3. Feedback sensors: Lastly, integrating feedback sensors ensures precise positioning and control, thereby enhancing overall performance. These features ensure voice coil actuators are at the forefront of cutting-edge technology.

Applications

The popular voice coil actuator applications are in:

- Aerospace.

- Medical equipment like surgical devices.

- Robotics as in robotic arms.

- Industrial automation, for example, positioning systems.

So are you looking to get the best out of voice coil actuators for that project? Check here and find some more reliable information.

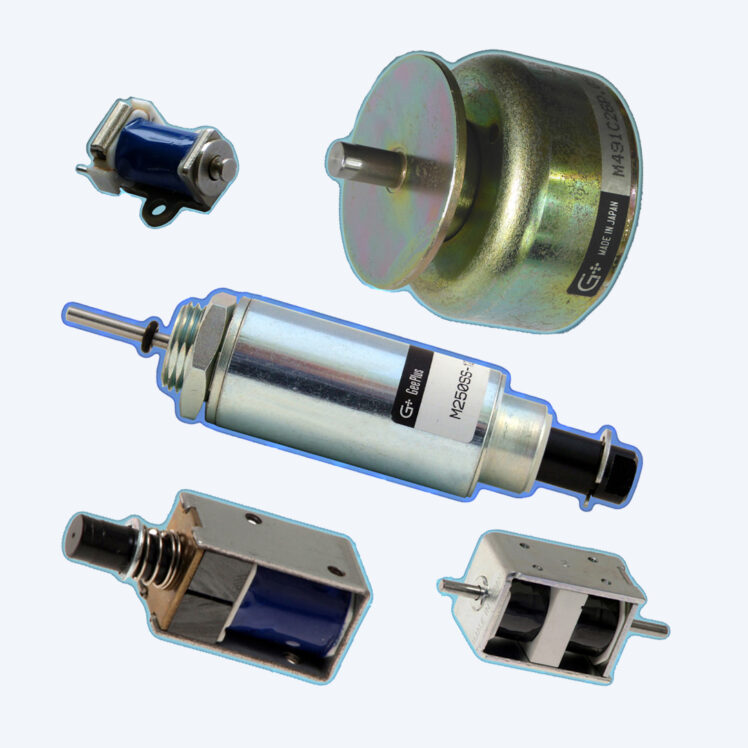

2. Solenoid actuators

Operating principles

Next up, we have solenoid actuators. These powerful devices operate using an electromagnetic solenoid to generate linear motion. When an electric current passes through the coil, it creates a magnetic field that moves a plunger or a rod. In general, solenoid actuators are popular for their rapid response time and robust performance.

Design considerations

- Types of solenoids: There are different types of solenoids, such as push-type or pull-type solenoids, each with its own advantages. Consider the specific requirements of your application to make the right choice.

- Stroke length and force output: Secondly, stroke length and force output are crucial factors to consider. Determine the distance the solenoid needs to travel and the amount of force it needs to exert.

- Feedback sensors: Lastly, integrating feedback sensors ensures precise control and positioning, allowing for enhanced performance.

Applications

Solenoid actuators find applications in various industries. They are mainstays in:

- Locks and latches.

- Automotive systems.

- Medical equipment.

- Vending machines and ATMs.

From unlocking doors to controlling fluid valves, solenoid actuators are reliable workhorses. They power countless everyday operations in these applications.

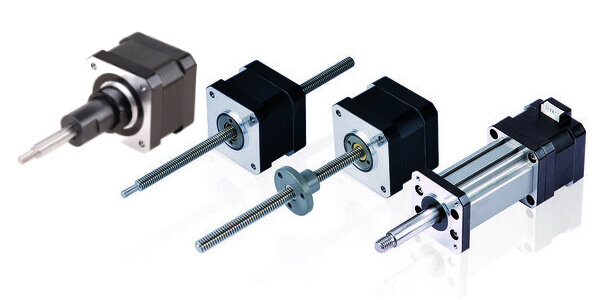

3. Linear stepper motors

Operating principles

These actuators operate using a magnetic rotor that moves in discrete steps, allowing for precise control and positioning. Linear stepper motors are known for their excellent repeatability and accuracy.

Design Considerations

When choosing linear stepper motors, certain design considerations come into play.

- Types of stepper motors: First, you have to choose between the permanent and hybrid magnets. They both offer unique benefits. So, choose the one that aligns with your project’s requirements.

- Resolution and accuracy: These are important factors to consider, as they determine the precision of motion.

- Feedback sensors: The feedback sensors play a vital role in achieving accurate positioning and control.

Applications

Linear stepper motors find applications in various industries and technologies. They include:

- 3D printing

- CNC machines

- Robotics

- Medical equipment

In general, linear stepper motors are useful in power systems that require precise and controlled linear motion. So, whether you’re prototyping a new product or working on a complex project, linear stepper motors offer the reliability and accuracy you need.

If you work in one of these industries or your work is connected with them, probably you have already met with these types of motors and it helped you in your projects or in practicing your skills. For example, people who work in 3d printing industry deal with linear stepper motors in their everyday work, so knowing its features and operational principles helps better understand how everything works and functions.

To get more information on available projects and work opportunities in the mentioned fields, particularly in 3d printing, browse Jooble where you can get the required data for your present or future working needs.

4. Moving magnet actuators

Operating principles

These versatile actuators utilize a moving magnet and a stationary coil to generate linear motion. By energizing the coil, a magnetic field is created, causing the magnet to move. Moving magnet actuators excel in delivering high forces and long stroke lengths.

Design considerations

When designing with moving magnet actuators, consider:

- Types of moving magnet actuators: The types available are linear or rotary. Try selecting the one that suits your application requirements.

- Force output and stroke length: They determine the actuator’s capabilities.

- Integration of feedback sensors: This ensures precise control and positioning, which in turn, allows for optimal performance.

Applications

Moving magnet actuators are useful in:

- Industrial automation.

- Aerospace.

- Medical equipment.

- Robotics, and more.

The moving magnet actuators power systems that require robust and reliable linear motion. Hence, they contribute to enhancing productivity and efficiency in machines.

Comparison of electromagnetic linear actuators

We have explored the different types of electromagnetic linear actuators. Here, we give you a glance at their key features and applications as compared in the table below:

| Actuator Types | Operating Principle | Design Considerations | Applications |

| Voice Coil Actuators | Magnetic field and coil | Coil types, magnet types, sensors | Aerospace, medical equipment, robotics. |

| Solenoid Actuators | Electromagnetic solenoid | Solenoid type, stroke length, force output, feedback sensors | Locks and latches, automotive, medical equipment, vending machines. |

| Linear Stepper Motors | Magnetic rotor, discrete steps | Stepper motor type, resolution and accuracy, feedback sensors. | 3D printing, CNC machines, robotics, medical equipment. |

| Moving Magnet Actuators | Moving magnet and coil | Force output, stroke length, sensors | Industrial automation, aerospace, medical equipment, robotics. |

Conclusion

Electromagnetic linear actuators offer a world of possibilities for applications in diverse industries. From voice coil actuators to solenoids, linear stepper motors, and moving magnet actuators, each type has its own strengths and unique characteristics. By understanding their operating principles, design considerations, and applications, you make informed choices for your projects.